Benefits of Powder Coating

Thermosetting Powder coating is a very popular way to paint parts, and there are numerous finishes and colors available. Pagan Paints & Chemicals Pvt. Ltd. provides a range of advantages over conventional painting methods, and it yields a durable, attractive finish. From its environmental impact to its cost, we’ll review the benefits of powder coating.

1. Very Efficient:

Due to electromagnetic charge used to hold the powder to the part produced by an electrostatic spray gun there is very little waste created in the process. In addition, powder coatings professionals can spray as much or as little powder as needed in a single application. Rather than waiting for each powder coat to dry before applying the next, this is all done in a single step, and will still cure evenly. This saves time and money in operating costs.

2. Low Cost:

Along with the money you’ll save by eliminating extra steps, powder coating is cost-efficient in a few other ways. The materials used are bought according to the job’s specifications. The Pagan Paints & Chemicals Pvt. Ltd. is less costly than paint, and it takes up less space when stored.

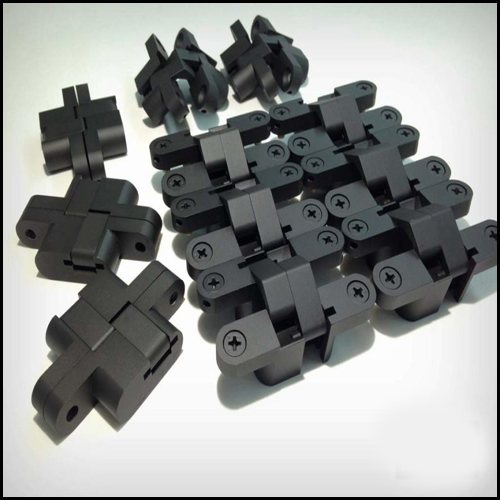

3. Durability:

As far as the finish is concerned, Thermosetting powder coating is more durable than most other options. When it cures, the powder will form a strong chemical bond in the process and create a flexible, durable finish. Powder coated parts are highly resistant to corrosion(Rust), flaking, and scratching.

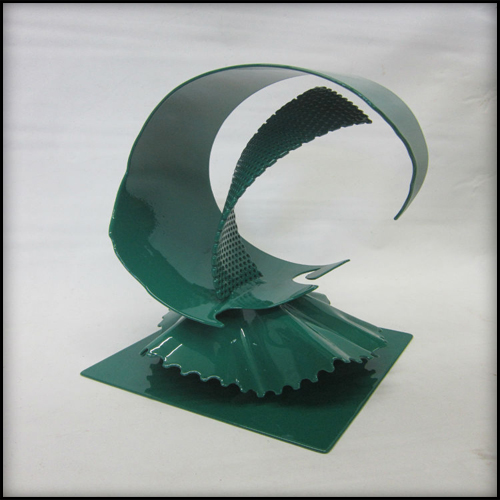

4. Variety:

While there are some common colors and finishes used in powder coating, one of the best assets of this method is the ability to completely customize your colors and finish. The Powder coating manufacturer will create a one of a kind powder blend that matches any colors, with the option to add texture like wrinkles or glitter, and a huge range of finishes from high gloss all the way down to matte. Few other high quality powder paint options can compete with this range and versatility.

5. Environmentally Safe:

Since the powder used in Thermosetting powder coatings is free of solvents and other chemicals, it is generally recognized as safe for use and for disposal. The process releases no known harmful chemicals into the atmosphere, and produces less overall waste throughout spraying. However, painters know not to inhale the powder and to wear protective gear to prevent skin contact.The raw materials used to manufacture Pagan Paints & Chemicals Pvt. Ltd. are REACH and ROHS certified thereby making it safe for the environment and also safe to touch.

6. Quality:

Both the application and curing process used in Pagan Paints & Chemicals Pvt. Ltd. systems create a quality finish that is unlike any other paint on the market. Since the powder melts and flows together, it creates an even surface across the entire unit. In addition, it is not subject to unevenness, running or dripping, which are common among wet paints. As a result, it doesn't require sanding or refinishing if a mistake is made.

7. Maintenance:

Pagan Paints & Chemicals Pvt. Ltd. coating is easy to maintain; no special solvents or cleaners are required. Because these coatings are so resistant to corrosion and damage, there’s no concern over rust and other cleaning related damage. In most applications, an occasional wipe with soapy water is enough to keep parts clean and useful for years into the future. It’s easy to see how mil spec powder coating is better than conventional paint in many areas. With the proper equipment, powder coatings decrease finishing time, improves quality, and leaves users with a variety of finish options. Not only will you be able to use and dispose of materials in an eco-friendly, cost-efficient way, but your customers will also appreciate the tough, durable finish. Visit us online or call today for more details.